No. 6555 Songze Avenue, Chonggu Town, Qingpu District, Shanghai, China

Non standard custom

Our are a factory engaged in customizing non-standard industrial spare parts

Provide full process services from small batch to mass production

![]() All uploads are secure and confidential.

All uploads are secure and confidential.

What We Do

Shanghai Yunyan Prototype & Mould Manufacture Factory is a professional enterprise for more than 17 years which OEM / ODM custom processing specialized in making injection/casting mould, 3D printing and CNC machining parts such as CNC machining parts, SLA/SLS 3D printing, mechanical designing and injection/casting/machining, stamping Production etc. Being worked on different projects with well-established customers from the US, Australia, the Middle East, Asia, and Europe for many years. We have very rich experience, good service, lower price and good quality advantages with delivery in time, we are looking forward to receiving your reply and getting altogether win-win.

CNC machining service

Precision CNC machining is the initial service category of our factory, which utilizes computer numerical control systems for precision machining. High performance cutting tools and advanced machine tools perform high-precision and efficient cutting, milling, turning and other processing operations on various materials. CNC machining is widely used in fields such as machinery, automobiles, aerospace, electronics, healthcare, etc. It can produce high-precision products such as complex shaped parts, molds, fixtures, etc. It has the advantages of high precision, high efficiency, and strong flexibility, and can meet various customization and batch production needs. If you need high-precision and high-quality spare parts for parts processing, CNC machining services will be your best choice.

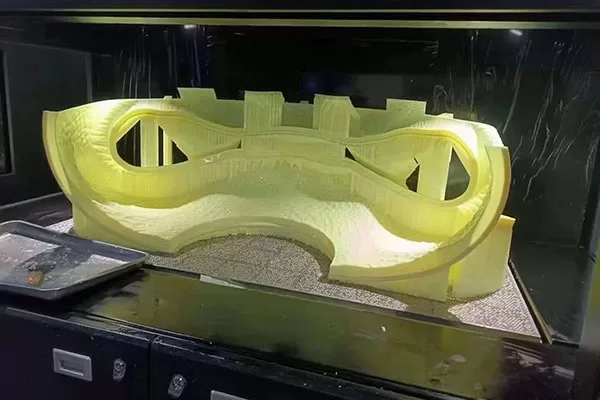

3D printing service

With the rise of 3D printing, it is a manufacturing technology based on 3D digital model files, which uses sticky materials such as powdered metal or plastic to construct objects through layer by layer printing. This service can provide customers with comprehensive services from design to prototype production, small batch production to batch production. 3D printing technology has the advantages of manufacturing complex items without increasing costs, achieving product diversification without increasing costs, no assembly, zero time delivery, unrestricted design space, no skill manufacturing, no space occupation, portability and mobility, reducing waste and by-products, unrestricted material combinations, precise physical replication, high material utilization, and personalized customized production. Whether you need rapid prototyping design or small-scale production of complex parts, 3D printing services can meet your needs and provide more efficient and flexible solutions for product development and production.

Sheet metal fabricate

Sheet metal processing is a processing technology for metal sheets, mainly including a series of process flows such as shearing, stamping, bending, welding, etc. This processing method can utilize various mechanical equipment and manual operations to convert the original metal sheet into components or products with specific shapes and functions. Sheet metal processing is widely used in mechanical manufacturing, automotive manufacturing, electronic equipment, aerospace and other fields, and can meet various complex and diverse parts processing needs. This process technology has the characteristics of high efficiency, high precision, and high flexibility, which can be customized according to customer needs and can also achieve mass production. Through sheet metal processing, flat metal sheets can be transformed into three-dimensional and practical products, bringing many conveniences to modern industrial production and people’s lives.

Carbon fiber custom

Carbon fiber components are components made of carbon fiber composite materials. Carbon fiber is a high-performance, lightweight reinforcing material with excellent mechanical properties and corrosion resistance. The production process of carbon fiber components includes the laying of carbon fiber cloth, resin infiltration, curing, and other steps. Compared to traditional metal materials, carbon fiber components have the characteristics of light weight, high strength, good stiffness, and excellent fatigue resistance. Therefore, carbon fiber components are widely used in fields such as aerospace, automobiles, sports equipment, medical equipment, etc., which can significantly improve product performance and reduce weight. At the same time, carbon fiber components also have good design and plasticity, which can meet the needs of various complex shapes and structures.

Maybe I can do more for you

Our can provide you with a full process service from sample to mass production,Please leave your contact information

Vacuum casting service

Vacuum casting service is a process service that utilizes vacuum technology to achieve mold casting. It uses polymer materials as casting materials, and in a vacuum environment, the materials are tightly adhered to the surface of the original mold through heating, pressure, and other methods, thereby producing castings that are consistent with the shape and size of the original mold. This service has the advantages of high casting accuracy, high efficiency, and low cost, and is widely used in product development and production in industries such as automobiles, electronics, home appliances, toys, etc. Vacuum casting services can provide customers with fast and accurate mold casting solutions, greatly shortening product development and production cycles, improving production efficiency, and reducing costs. At the same time, this service can also meet the personalized and customized needs of customers, providing them with a more comprehensive mold casting service experience.

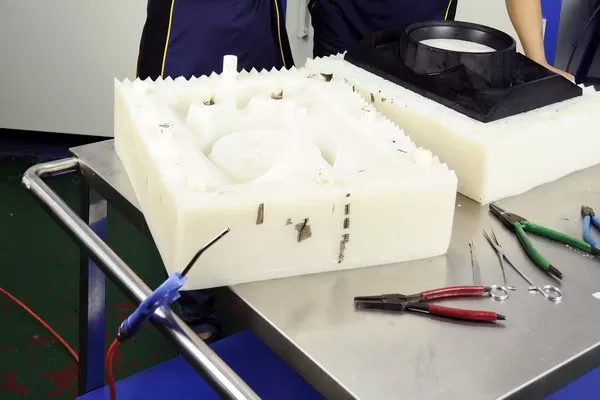

Mold manufacturing services

Mold is the optimal solution for mass production, with professional and high-precision manufacturing quality, providing customers with high-quality products and comprehensive manufacturing solutions. We cover all aspects of mold design, material selection, processing and manufacturing, debugging and optimization, ensuring that the final mold can meet the precise requirements and efficient production needs of customers.

As the basic process equipment for industrial production, molds are known as the “mother of industry” and are widely used in various fields such as electronics, automobiles, home appliances, toys, etc. Mold manufacturing services have rich industry experience and advanced technical strength, capable of addressing various complex and high-precision mold manufacturing challenges.

Our mold manufacturing services focus on quality and delivery time, using advanced processing equipment and processes to ensure the accuracy, stability, and service life of the molds. At the same time, we provide one-stop services from requirement analysis, solution design to mold manufacturing, debugging, and delivery, with full tracking to ensure the smooth progress of the project.

By choosing our mold manufacturing services, you will receive professional technical support, high-quality product quality, and comprehensive after-sales service to help your project and business development succeed.

Send us a message

Email: info@ymolding.com

Address: No. 6555 Songze Avenue, Zhaoxiang Town, Qingpu District, Shanghai, China

Our Clients

Our customers come from North America, South America, Europe, Oceania and Asia, and we look forward to getting win-win cooperation with customers all over the world.

Frequently Asked Questions

What industries do you service?

Our provide manufacturing for all industries that require metal and polymer parts.

These industries include automobiles, machine manufacturing, railways, aerospace, electronics, toys, sports goods, new energy, etc.

Contact us if you have any questions about how we can help you with your application.

What is the proceesing for the quote ?

Our can quote from your 2d/3d formats design drawings,quote the price to clients after got the within 2 hours;

Do you do the surface treatments please ?

yes, sure . we do the surface treatments ,for instance ; chromated, powder coating,Anodizing, laser etching as well as painting ;